Cameron Falls G.S. Unit Rebuild

The rebuild at Cameron Falls is a great example of how all of the different services of Soo Foundry join together to create a quality

The rebuild at Cameron Falls is a great example of how all of the different services of Soo Foundry join together to create a quality

Working with the manufacturer, SFM replaced a jaw crusher at a remote mine. The old crusher was disassembled and removed without damaging any components. The

Equipped with the most state-of-the-art vibration monitoring equipment, we can monitor and diagnose equipment such as: pumps, fans, compressors, motors, gearboxes and many more. We

Working with the customer, SFM designed and manufactured a custom infeed roll assembly to increase throughput in a lumber application. This machine was designed to

Heavy repairs are often needed when disaster strikes. These frames were severely cracked and needed to be repaired within a two-week lead-time. The cracks were

We have your back when it comes to emergency breakdowns. Within one week, SFM designed and implemented a repair for this damaged bearing housing. This

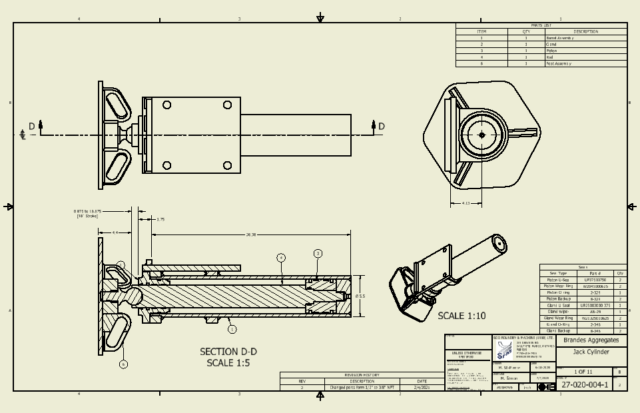

SFM can provide custom hydraulic applications such as these jack cylinders with independent foot pads. These cylinders were designed with the customer to improve their

From idea to fully functional product, this grizzly screen was designed and fabricated by SFM to meet all of the customer requirements. Special attention was

SFM has the equipment and personnel to perform laser shaft alignments. Alignment is common within all sectors of industry. We can perform alignments of motors,

Soo Foundry repairs a range of heavy equipment buckets, often times repairing larger loader and excavator buckets used in quarries. Repairs range from replacing wear